High-speed steel has been an integral part of the manufacturing sector. High-speed steel and HSS cutting tools have always dominated the global market, and their demand is expected to grow even more. Despite the increasing competition from solid carbide products, HSS remains the popular option in the industrial sector. In fact, cutting tools made from HSS is considered to be the most suitable solution for mass production, keeping in mind the various factors such as tool life, productivity, flexibility, and cost of manufacturing. But what is the composition of this material? And what are its distinct advantages?

These primary questions regarding high-speed steel will be addressed below:

HSS Composition

High-speed steel is typically composed of cobalt, tungsten, chromium, vanadium, molybdenum, and carbon. The different grade types of HSS depend on the varying composition of the above elements. For instance, adding cobalt enhances heat resistance, retains hardness, and slightly increases heat conductivity. On the other hand, carbon is the one responsible for providing the basic hardness of HSS while increasing its wear resistance.

The introduction of tungsten is intended to provide greater cutting efficiency and higher resistance to tempering, while simultaneously improving the material’s hardness and temperature resistance. Scaling is prevented by adding chromium and the addition of molybdenum in HSS offers similar properties as tungsten. Finally, vanadium is added to further increase the strength and wear resistance of HSS.

HSS Advantages

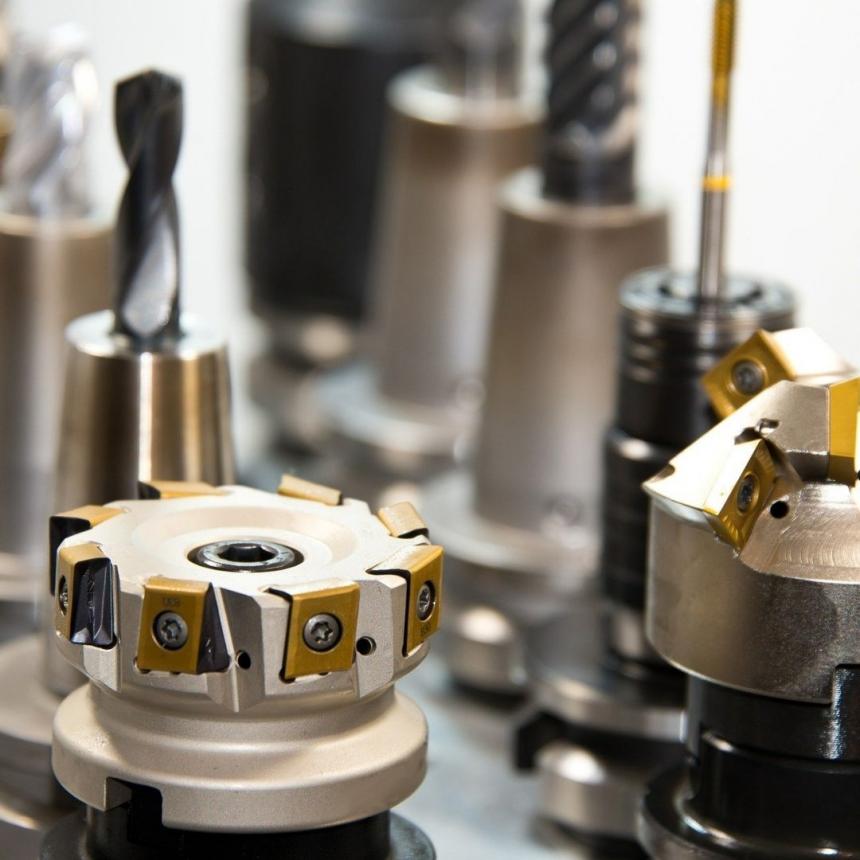

- The primary properties of HSS are outstanding hardness, excellent wear resistance, and toughness. Due to these characteristics, high-speed steel tools can resist vibrations, regardless of the type of machine and conditions of the clamp.

- These properties also help prevent mechanical shocks at tooth level during machining operations.

- Moreover, HSS tools can also withstand varying lubrication that can result in thermal changes.

- Finally, tool manufacturers are now capable of producing very sharp cutting edges because of the inherent strength of HSS. These cutting tools are highly efficient and offer a superior surface quality.

With a better understanding of high-speed steel, you can now use it optimally for your business or send it for recycling.

Alnor Industries Ltd. accepts all varieties of HSS scraps, including steel turnings, HSS chip and inserts, HSS drill bits, and a lot more. To learn more about our company and services, contact us today.